Making sustainable algae harvesting a reality

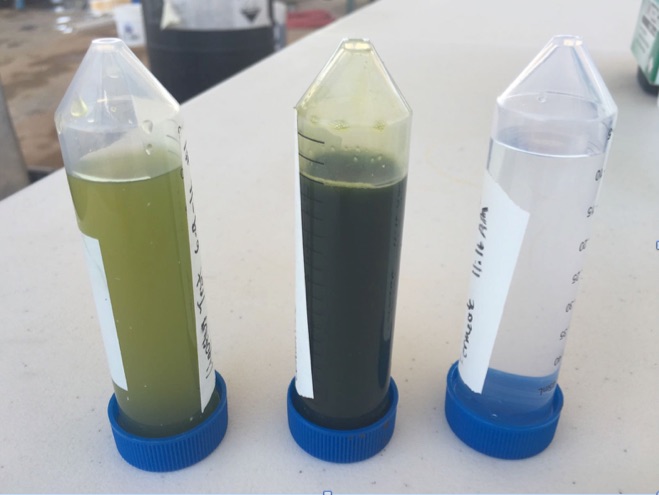

LiqoCap® membranes are at the core of Liqoflux’s algae harvesting solutions. Designed for high efficiency, these membranes achieve exceptional algae concentration levels while enabling water recycling for sustainable production.

Reduce water waste with seamless recycling and optional disinfection using ozone or UV technologies for cleaner production systems.

From pilot facilities to large-scale commercial operations, our solutions grow with your algae production needs.

A smarter, more sustainable algae industry

Our proven technologies ensure cost-effective, automated systems that are easy to operate and maintain. With over a decade of global expertise, Liqoflux is the trusted partner for advancing algae harvesting and water treatment solutions.

We support you to realize high performance algae harvesting solutions.

Liqoflux delivers the right technical solution for each part of the algae harvesting and water treatment process.

The Benefits

News

Leading the way in innovative algae harvesting and water treatment solutions, powered by cutting-edge technology.